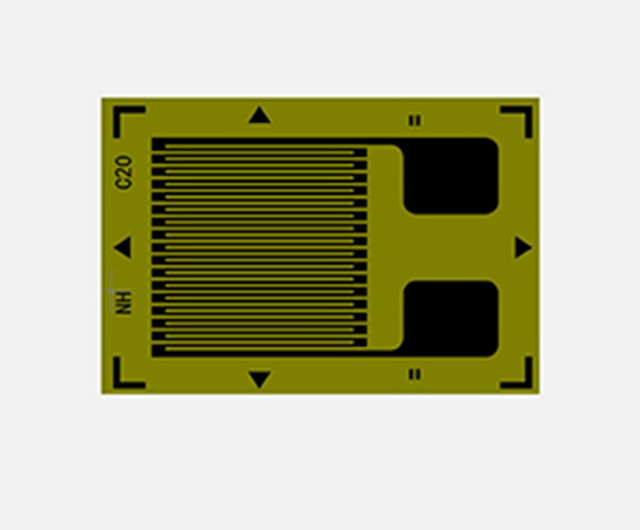

Common problems and solutions for strain gauge use

2022-08-05

1. Zero Drift

We know that zero drift is the easiest to occur and the most difficult to control in strain gauge applications. Zero drift is affected by various factors, which we will analyze in detail below.

(1) Influence of Insulation Resistance

Insulation resistance is an important electrical performance indicator of strain gauges. Its magnitude is most directly reflected in the zero drift of the strain gauge. The so-called insulation resistance is the resistance between the sensitive grid of the strain gauge and the measured component or elastic body. If the insulation strength is reduced or low, leakage current will be generated between the sensitive grid and the component or elastic body, which will affect the zero stability of the strain gauge, i.e., drift. The factors that cause this problem and how to solve it are of great concern to us.

A. The strain gauge is not cleaned or not cleaned thoroughly after welding, causing a decrease in insulation strength. This is mainly due to the presence of flux during welding. Flux is a material with good activity and wettability, which facilitates the bonding of solder and solder ends. However, it is also an ionic substance. If it is not cleaned or not thoroughly cleaned, cations will migrate, causing the insulation strength to not meet the requirements.

B. During strain gauge welding, the soldering iron leaks electricity or the temperature is too high or the time is too long, causing the strain gauge substrate to break down, resulting in a decrease in insulation strength. For this problem, the soldering iron must be tested to ensure its insulation strength at the welding end to avoid breakdown or harm to personnel; during welding, the temperature must not exceed 350℃, and short-time multiple welding should be used to avoid substrate breakdown.

C. The strain gauge becomes damp, causing a decrease in insulation strength. This phenomenon is mainly caused by poor protection of the strain gauge during use or excessive environmental humidity during use. This drift is similar to A, so in the application process, the environmental humidity must be controlled within 60%; during application, the strain gauge must be protected to prevent water vapor from entering and affecting the stability of the strain gauge.

D. The strain gauge is pierced, causing a decrease in insulation strength. This problem mainly occurs during the patching or bridging process. For example, a hard object clamps the strain gauge or component, surface burrs or scratches of the elastic body pierce the strain gauge, or the soldering iron tip is too sharp to pierce the strain gauge during welding.

(2) Influence of Patching Defects

This problem mainly occurs during the patching process.

A. There is a void phenomenon after patching, causing zero drift of the strain gauge. This phenomenon mainly manifests as a foreign body sensation and blooming on the back of the strain gauge substrate when inspected with light. At the same time, when a soft object is applied to the strain gauge, the resistance value of the strain gauge will change, and when it is removed, the resistance value will quickly recover. Due to the void, the local heat increases when the strain gauge is energized, resulting in thermal drift.

B. The adhesive layer is too thick during patching, or glue edges and bulges are produced after patching, causing zero drift of the strain gauge. This phenomenon mainly manifests as a layered feeling on the back of the strain gauge, more residual glue around it, and glue edges and bulges after curing. The main reason for this phenomenon is that the surface of the component is not cleaned, there are particles, or the glue is applied unevenly or there is too much glue.

(3) Strain Gauge Floating Grid or Sealing Layer Peeling, Causing Zero Drift of the Strain Gauge

A. Strain gauge floating grid. It mainly manifests as needle-like bright spots on the surface of the strain gauge when observed with side light, or twisting of the sensitive grid when observed with a microscope. The cause of this problem may be excessive environmental humidity or excessive water content in the cleaning solvent, causing the strain gauge to become damp.

B. Sealing layer peeling. It mainly manifests as partial or complete peeling of the sealing layer. The main reason for this problem is insufficient bonding force between the sealing layer and the sensitive grid, causing uneven heat dissipation of the sensitive grid.

2. Abnormal Resistance After Patching

Generally, the resistance of the strain gauge will have a slight change or remain unchanged after patching, but there are often changes. The factors causing this problem are as follows:

(1) Excessive pressure during pressure curing causes abnormal resistance after patching. Reduce the pressure appropriately. Recommended pressure: 0.1Mpa-0.3Mpa.

(2) Uneven pressure during pressure application causes deformation of the strain gauge sensitive grid and abnormal resistance. This problem is mainly caused by non-standard pressure application fixtures, resulting in uneven force on the strain gauge.

(3) The radius of curvature of the tooling design does not match the component, causing deformation or bulging of the strain gauge.

(4) After a period of use, the resistance becomes abnormal. This problem is mainly caused by the presence of air bubbles, individual voids, or unreliable welding inside the strain gauge.

3. Surface Defects After Patching

From the above content, it can be seen that the main defects of patching are voids, bulges, and uneven glue layers. As long as bulges and pits are not in the force-bearing part of the sensitive grid, they can be used. For these defects, defective ones should be removed to ensure patching quality. At the same time, resistance and insulation resistance should be checked.

Previous page