The effect of surface treatment of foil materials on the peel strength of different adhesives

2021-01-11

Abstract

Most domestic manufacturers of strain gauges use solvent cleaning on the foil surface before applying adhesive. However, domestic foil manufacturers have already cleaned the foil once before it leaves the factory. Studies have found that different films exhibit different bonding properties on the foil surface. For polyimide films, not cleaning the foil before use results in greater peel strength after bonding and a more stable structure. Cleaning the foil surface has no significant effect on the bonding of phenolic resin films. However, epoxy films exhibit better bonding performance after cleaning the foil surface.

Keywords: Strain gauge, Foil, Polyimide, Epoxy resin, Phenolic resin

0 Preface

In 1856, Thomson, while laying the transatlantic submarine cable, discovered that the resistance of the cable changed when subjected to mechanical deformation. Between 1936 and 1938, Professor Simmons of the California Institute of Technology and Professor Ruch of the Massachusetts Institute of Technology simultaneously developed paper-based resistance strain gauges. After about several decades of development, the accuracy of resistance strain gauges made significant progress in the early 1970s. Following the development of the electronics industry and computing technology, resistance strain gauges have seen significant advancements in product standardization, serialization, and large-scale production processes [1].

Modern society is gradually entering an era of ubiquitous connectivity and data dominance. Sensors, as the terminals of the Internet of Things and the source of data acquisition, provide "sensory" functions to all things, and are more accurate and have a wider range of perception than human senses [2]. In recent years, the demand for resistance strain gauges has increased significantly both domestically and internationally. However, compared to developed countries such as Germany, the United States, and Japan, the gap is quite significant in the research and development of high-quality resistance strain gauges and their manufacturing processes. One of the reasons for this gap is the bonding problem between the resistive sensitive grid and the substrate material.

To improve the stability of the bonding between the resistive sensitive grid and the substrate material, domestic manufacturers clean the surface of the alloy foil before applying adhesive or bonding. Different manufacturers have different cleaning processes. This paper studies the effect of different surface treatment processes of Constantan and Evanohm alloy foils on the peel strength of the adhesive on their surfaces.

1 Experiment

1.1 Reagents and Raw Materials

Acetone (industrial grade, Nantong Xinquan Chemical Raw Materials Co., Ltd.), Methyl ethyl ketone (industrial grade, Nantong Xinquan Chemical Raw Materials Co., Ltd.), Potassium carbonate (analytical grade, Shanghai National Medicines), Potassium hydroxide (analytical grade, Shanghai National Medicines), Absorbent cotton (Guangzhou Jiaying Non-woven Fabric Factory), Polyimide adhesive (self-made), Epoxy resin adhesive (self-made), Phenolic resin adhesive (self-made), Constantan alloy foil (5μm thickness, Shanghai Yu'er), Evanohm alloy foil (5μm thickness, Shanghai Yu'er).

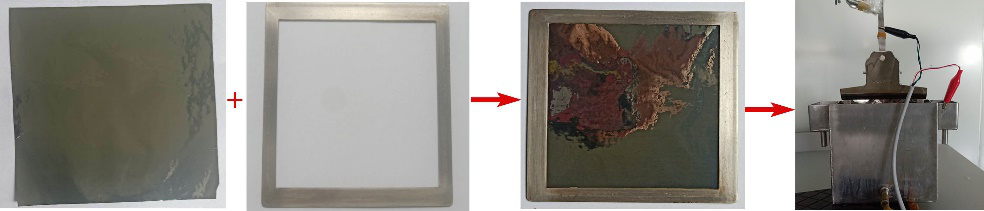

1.2 Surface Treatment and Adhesive Application Process of Alloy Foil

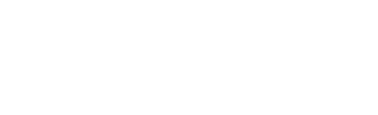

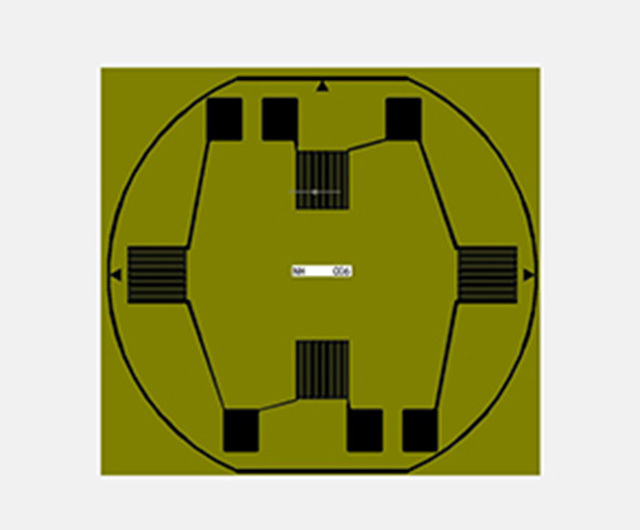

As shown in Figure 1, the foil is first placed on a horizontal surface for scrubbing. Absorbent cotton dipped in methyl ethyl ketone is used to scrub once, then absorbent cotton dipped in acetone is used to scrub once, and finally absorbent cotton dipped in methyl ethyl ketone is used to scrub once. It is then dried at 100℃ for 20 minutes. The dried foil is bonded and fixed to a titanium alloy frame, and then, as shown in Figure 1, adhesive is applied to the alloy foil. 3±0.1 grams of adhesive is applied to a 100mm×100mm area. The speed of the adhesive applicator is 650 rpm, and the application time is 7 seconds.

Figure 1 Traditional foil adhesive application process

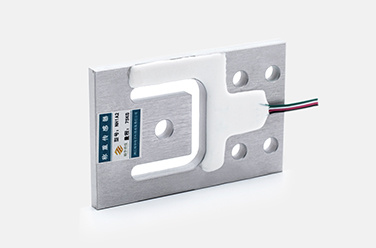

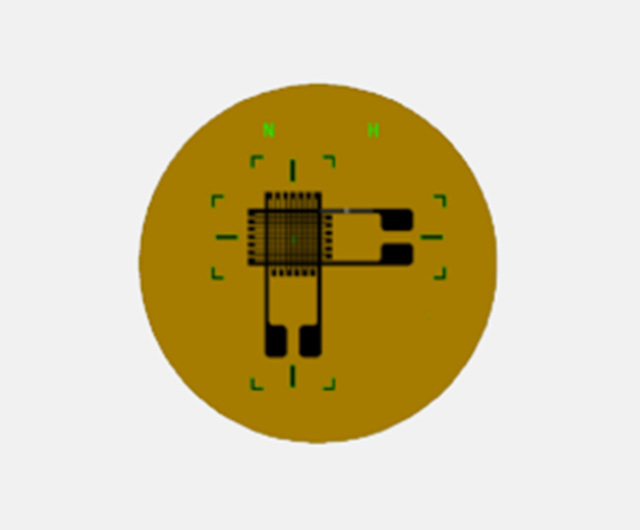

As shown in Figure 2, electrochemical cleaning is used to clean the alloy foil. The electrolysis process uses a two-electrode constant current electrolysis process. The electrolyte is a 30g/L potassium carbonate aqueous solution. The current density during electrolysis is 4A/dm2, and the counter electrode is a stainless steel electrolytic cell. First, the foil is used as the cathode for electrolysis for 5 minutes, then the anode for 30 seconds, and then repeatedly rinsed with water and dried at 100℃ for 20 minutes. The adhesive application process is the same as above.

Figure 2 Electrochemical cleaning of foil

1.3 Curing Process of Adhesive

Polyimide adhesive curing process: 180℃ for 1 hour; Epoxy resin adhesive curing process: 185℃ for 3 hours; Phenolic resin adhesive curing process: 190℃ for 2 hours.

1.4 Peel Strength Test

The peel strength test is performed according to national standard GB/T 2792-2014. The strength test uses a Haida multi-functional tensile testing machine (HD-B609B-S) at a test rate of 80mm/min.

2 Results and Discussion

2.1 Surface Bonding Performance of Constantan Foil

Figure 3 shows the tensile peel process of three different films on the surface of Constantan foil. In the tensile peel process of the epoxy film, the scrubbing of the Constantan foil surface has a significant effect on the peel strength of the epoxy film. Scrubbing the Constantan foil surface can significantly increase the peel strength and the stability of the bonding between the foil and the film. For phenolic resin films, which are commonly used by domestic enterprises, the scrubbing of the foil surface has no significant effect on the peel strength of the phenolic resin film. At the same time, the difference between the maximum and minimum peel strength of the phenolic resin film during the tensile peel process is relatively large, indicating that the bonding structure between the Constantan foil and the phenolic resin film is unstable, which will ultimately affect the stability of the strain gauge product.

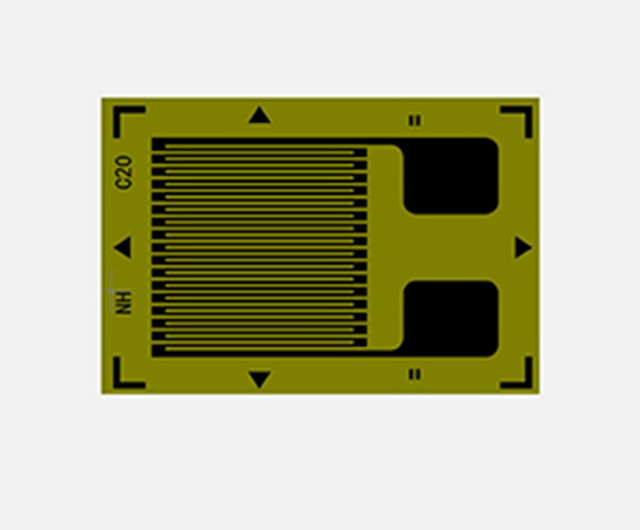

For PI film, unexpected results were obtained. The peel strength between the un-scrubbed foil and the PI film was significantly higher, and the bonding structure between the PI film and the Constantan foil was relatively stable. The difference between the maximum and minimum peel strength was less than 11 gf, indicating that scrubbing the Constantan foil produced the opposite result. Further research found that manually scrubbing Constantan foil with a thickness of less than 5μm easily forms wrinkles on the foil surface, as shown in Figure 4. These wrinkles affect the wettability of the adhesive, and the solvent evaporation in the adhesive and the stress concentration in the film during curing lead to an unstable bonding structure and low peel strength.

Figure 3 Tensile peel process of different films on the surface of Constantan foil

Figure 4: Wrinkles on the foil surface after wiping

2.2 Surface Bonding Performance of Ivan Foil

Figure 5 shows the tensile peel-off process of three different films on the surface of Ivan foil. It is clear that the epoxy film has the lowest peel strength on the surface of the Ivan foil, all less than 80 gf. Moreover, the effect of scrubbing the foil surface on the peel strength is very significant. The peel strength of the epoxy film on the scrubbed Ivan foil surface is almost twice that of the un-scrubbed foil surface. For phenolic film, the scrubbing and cleaning of the Ivan foil surface did not significantly affect the peel strength of the film, with peel strength greater than 176 gf and a fluctuation range less than 34 gf.

The peel strength of the PI film on the Ivan foil is relatively high, with the maximum peel strength approaching 400 gf, but with large fluctuations, especially the upper and lower fluctuation range of the PI film on the scrubbed foil surface reaching 125 gf. However, the overall performance of the un-scrubbed foil is better, with peel strength greater than 300 gf and a fluctuation range less than 46 gf.

Figure 5: Tensile peel-off process of different films on the surface of Ivan foil

Different films exhibit different bonding performance on different foil surfaces. This is related to the characteristics of the foil surface on one hand, and to the characteristics of the film itself on the other. In addition, the solvent used in the adhesive also has a significant impact on the bonding. Because solvents with stronger dissolving power can dissolve some organic contaminants on the foil surface into the adhesive layer, thereby enhancing the stability of the bonding structure.

3. Conclusion

Domestic manufacturers of strain gauges mostly use solvent cleaning on the foil surface before applying the adhesive. However, the cleaning of the foil surface has different effects on the bonding performance of different films on the foil surface. First, for PI adhesive, scrubbing the foil surface reduces the bonding stability of the film on the foil surface. This may be because the scrubbing process increases wrinkles on the foil surface, and these wrinkles reduce the stability of the bonding structure. Therefore, the scrubbing process should be eliminated when using PI adhesive. Second, for epoxy adhesive, scrubbing the foil surface significantly increases the stability of the bonding structure, so the pre-use scrubbing process should be maintained. Third, for phenolic adhesive, scrubbing the foil surface has no significant effect on the stability of the bonding structure, so the pre-use scrubbing process should be eliminated.

References:

1. Lin Jing, Ni Xidong, Qi Peiyun, Chen Xi, Feng Wei. Bonding technology of strain gauges in strain-type torque sensors. Shipbuilding Engineering, 2012, 34(1): 52-53.

2. He Yanxiang, Sun Fajun, Li Qingan, He Jing, Wang Lümeng. Review of Public Key Mechanism Research in Wireless Sensor Networks. Journal of Computer Science, 2020, 03: 381-408.

3. Shi Yu, Yao Chengwei, Li Qi. Development of an epoxy-phenolic base adhesive for room temperature strain gauges. Thermosetting Resin, 2009, 24(4): 37-39.

Previous page