-

Products

-

-

-

-

Contact Us

What are the differences between a tension sensor and a pressure sensor?

2024-05-08

Tensile sensors and pressure sensors are two commonly used sensors with important applications in industrial control, automotive, and aerospace fields. Although both are used to detect force, there are some differences in their practical applications.

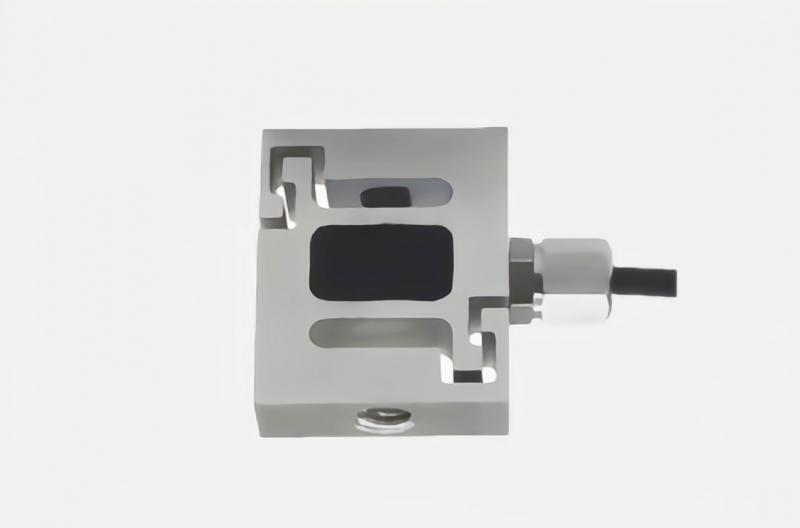

First, tensile sensors and pressure sensors differ in the direction of force they detect. Tensile sensors primarily detect tensile or pulling force, that is, under conditions where a stretching force is generated between two objects. Pressure sensors, on the other hand, are used to detect pressure, that is, when the surface of an object is subjected to external pressure. Therefore, from an application perspective, tensile sensors are more suitable for measuring the force of ropes, wires, etc., under tension, while pressure sensors are more suitable for measuring the pressure of liquids, gases, and solid surfaces.

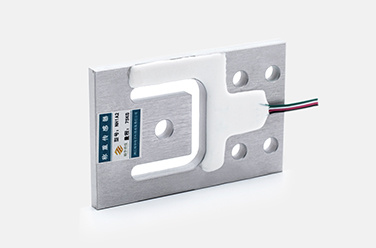

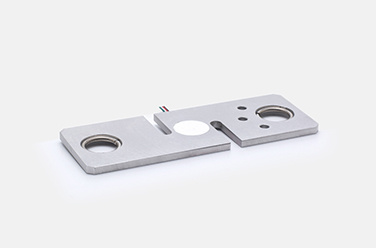

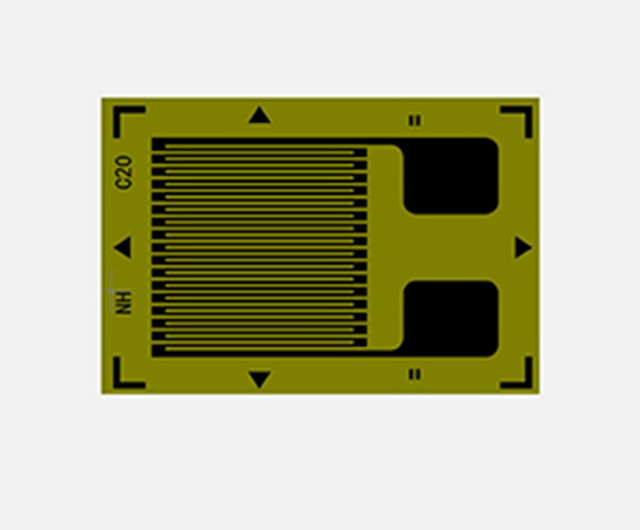

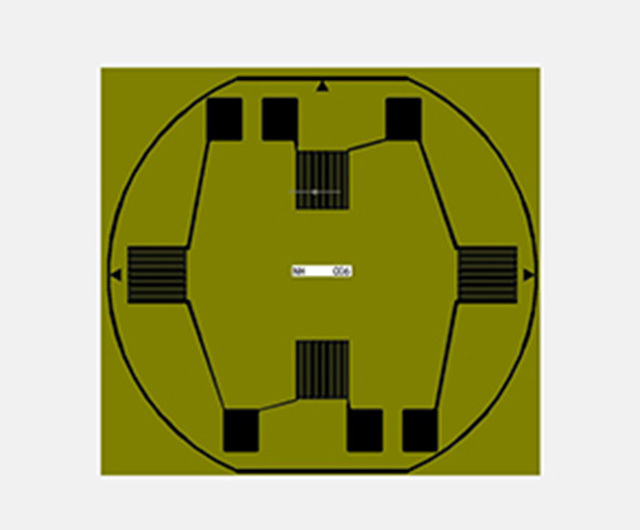

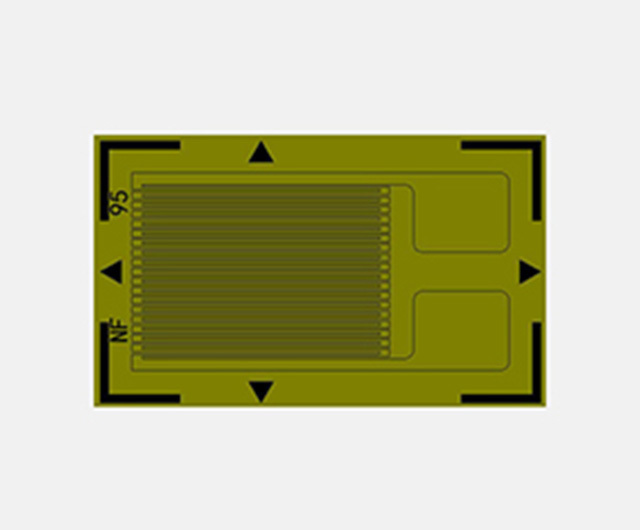

Second, tensile sensors and pressure sensors also differ in structure. Tensile sensors usually consist of a pair of measuring rods or strain gauges. When an external force acts on the measuring rod or strain gauge, it causes deformation, generating an electrical signal. The magnitude of the tensile force is obtained by measuring the change in the electrical signal. Pressure sensors, however, typically use thin-film strain gauges, miniature piezoresistive gauges, or piezoelectric sensors. When an external force acts on the surface of the pressure sensor, it causes deformation of the sensitive element, generating an electrical signal. The magnitude of the pressure is obtained by measuring the change in the electrical signal.

In addition, tensile sensors and pressure sensors also differ in measurement range and accuracy. Because different application scenarios require different measurement accuracy and ranges, the design parameters of tensile sensors and pressure sensors will also differ. Generally, the measurement range of pressure sensors is usually larger, covering a range from a few Pascals to several kilopascals, while the measurement range of tensile sensors is narrower, generally ranging from a few grams to several kilonewtons. Furthermore, because pressure sensors need to consider the influence of the external environment, their design usually takes into account factors such as temperature and humidity to ensure the accuracy and stability of the measurement results.

In summary, although both tensile sensors and pressure sensors are used to detect force, they have different characteristics in practical applications. By thoroughly understanding the differences between them, we can better choose the appropriate sensor to improve the accuracy and stability of the measurement. In future engineering practices, we should select tensile sensors or pressure sensors based on the specific application scenario and needs to ensure the desired measurement effect.

Hotline

Technical Support

Address

No. 1, Building 1, Yin Cang Road, Green Industry Cluster, Quzhou City, Zhejiang Province

Follow us

Copyright © 2024 Zhejiang Nan Hua Electronic Technology Co., Ltd. | Powered by www.300.cn