In what fields are aluminum elastomers widely used?

2024-04-28

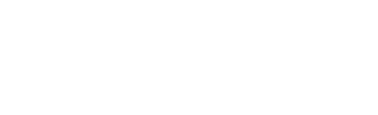

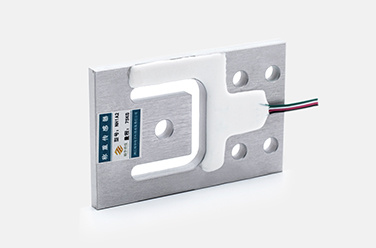

Aluminum elastomer is an elastic material made of aluminum alloy. It possesses excellent elasticity, wear resistance, and corrosion resistance, leading to widespread applications in numerous fields.

Firstly, in the aerospace field, aluminum elastomers are widely used in the manufacturing of aircraft structural components and parts. Due to their superior strength and wear resistance, they can withstand complex forces and pressures during flight, ensuring aircraft safety and stability. Simultaneously, the lightweight nature of aluminum elastomers aligns with aircraft design requirements, contributing to reduced aircraft weight and improved fuel efficiency.

Secondly, in the automotive industry, aluminum elastomers are also widely used in the manufacturing of automotive components. Car wipers, suspension systems, and engine parts can all be made using aluminum elastomers, enhancing vehicle safety and durability. The high strength and corrosion resistance of aluminum elastomers also reduce component wear and maintenance costs during vehicle use.

Furthermore, in the construction field, aluminum elastomers are often used in the manufacturing of building exterior decorations, window frames, and roofing materials, exhibiting excellent weather resistance and decorative properties. Because aluminum elastomers are lightweight and easy to process, they reduce building loads, improving building lifespan and appearance.

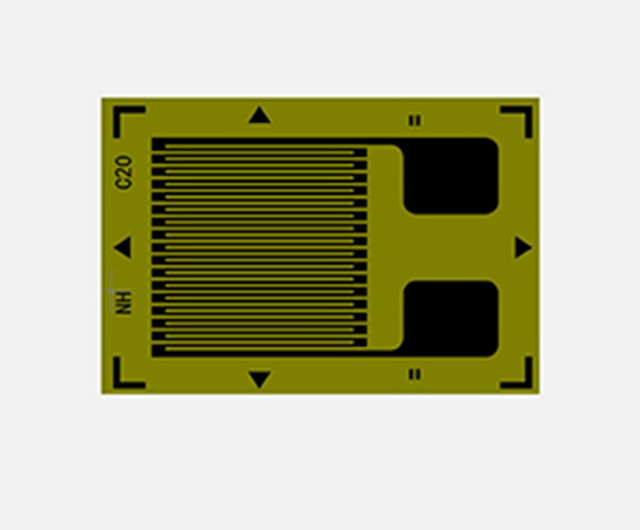

In the electronics industry, aluminum elastomers are also widely used in the manufacturing of electronic product casings and heat sinks. Due to their excellent thermal conductivity and heat dissipation performance, they effectively protect the stability and reliability of electronic products.

Aluminum elastomer is a novel material with excellent mechanical properties and elastic characteristics, thus possessing broad application prospects in the market. Firstly, aluminum elastomers have significant applications in aerospace, automotive, and high-speed rail industries. Due to their lightweight nature and high strength, they can reduce product weight, improve product performance, and lower energy consumption, aligning with the modern industrial demand for energy conservation and environmental protection. Secondly, in the construction field, aluminum elastomers can also be used to manufacture various doors, windows, and curtain walls, possessing good corrosion resistance and durability, enhancing the overall quality and aesthetics of buildings. Furthermore, aluminum elastomers can also be used to manufacture sporting goods, toys, and electronic products, indicating significant market potential.

With continuous technological advancements and increasing demands for product quality, aluminum elastomers, as a novel material, have broad application prospects. Firstly, with the development of the automotive industry, there is a growing demand for lighter automotive components that maintain sufficient strength and durability; aluminum elastomers are the ideal choice to meet this need. Secondly, in the aerospace field, due to their outstanding mechanical properties and elastic characteristics, aluminum elastomers can be used to manufacture aircraft components, improving aircraft performance and safety levels, thus presenting very broad market prospects.

Furthermore, in the construction field, with increasing demands for the performance and quality of building materials, aluminum elastomers will gradually replace traditional materials, becoming the preferred choice for building doors, windows, and curtain walls. Aluminum elastomers offer strong corrosion resistance and a long lifespan, not only enhancing the overall quality and aesthetics of buildings but also meeting people's needs for environmentally friendly and energy-efficient building materials.

In summary, aluminum elastomers, as a novel material, have broad application prospects in aerospace, automotive, and construction fields. With continuous technological advancements and growing market demand, aluminum elastomers are expected to see wider application and promotion in the future, becoming one of the mainstream materials in various industries.

Next page