-

Products

-

-

-

-

Contact Us

What are some noteworthy aspects of the production process for aluminum elastomers?

2024-05-24

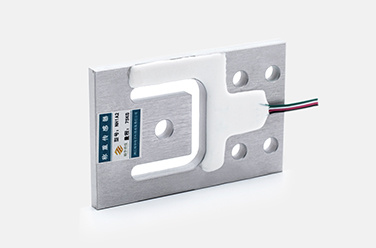

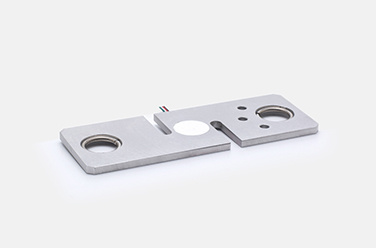

Aluminum elastomers are aluminum alloy products with good deformation and elasticity, widely used in automobiles, aerospace, construction, and other fields. During the production of aluminum elastomers, several key processes require attention from producers to ensure product quality stability and improve production efficiency. Here are some key production processes worth noting:

Material Selection: The production of aluminum elastomers begins with raw material selection. High-quality aluminum alloy materials should have high strength, excellent plasticity, and good weldability, balancing process performance and economy.

Forming Process: The forming process is a key factor affecting product quality. Common forming processes include stamping, stretching, and casting; the appropriate forming process must be determined based on the product's shape and size.

Heat Treatment Process: Heat treatment is an important process affecting the strength and hardness of aluminum elastomers. Through proper heat treatment, the mechanical properties of the product can be improved, enhancing its hardness and wear resistance.

Surface Treatment: Surface treatment improves the product's appearance and corrosion resistance. Different surface treatment processes, including spraying, electroplating, and anodizing, require strict control of process parameters and procedures to ensure consistent results.

Assembly Process: Aluminum elastomers usually need to be assembled into other components. The assembly process should ensure precise component matching and reliable assembly. During assembly, care must be taken to avoid damage and misassembly.

Quality Control: A complete quality control system is needed throughout the production process to ensure that the product meets requirements. Through strict inspection of raw materials, semi-finished products, and finished products, potential quality problems can be identified and addressed promptly.

In summary, the production process of aluminum elastomers involves many technical aspects, requiring producers to pay close attention to each step and maintain professional technical skills. Only by perfecting every detail can product quality stability and production efficiency be ensured. Continuously innovating and improving process technology will make products more competitive in the market, meet customer needs, and achieve sustainable development.

Previous page

Hotline

Technical Support

Address

No. 1, Building 1, Yin Cang Road, Green Industry Cluster, Quzhou City, Zhejiang Province

Follow us

Copyright © 2024 Zhejiang Nan Hua Electronic Technology Co., Ltd. | Powered by www.300.cn